In addition, Schmelz gives lectures for young biologists, biotechnologists and biochemists at the Technische Universität Braunschweig. It is important and satisfying to him to transfer knowledge to young people. He sees his work with bachelor and master students, trainees and apprentices as an investment into the future.

He discovered structural biology rather by coincidence. Even early on in his studies of physical biochemistry in Darmstadt, he had a strong desire to spend some time abroad – a dream he made come true when he worked as a doctoral student with James Naismith at the University of St Andrews in Scotland. The research group focused on structural biology and Schmelz kept to this focus later on. A guest lecture of a German scientist named Dirk Heinz was his first contact to the HZI, followed by an appointment after his unsolicited application in 2010 – first with Dirk Heinz for three years, then with Andrea Scrima and presently with Wulf Blankenfeldt. "I never regretted embarking on this path," Schmelz says.

Stefan Schmelz has published 15 protein structures since 2010 – and there are some more in his pipeline. And he is well connected: Working with Rolf Hartmann of the HIPS, he studies proteins that contribute to the production of biofilms by Pseudomonas aeruginosa, whereas his work with Melanie Brinkmann of the HZI solved the structure of a tegumental protein of herpes viruses in order to study its influence on the immune defence. A protease that destroys lung tissue in Legionnaires' disease is the research topic of a collaboration with the TU Braunschweig, in the scope of which he and Andriy Luzhetskyy of the HIPS develop biosensors for effective screening of new antibiotics.

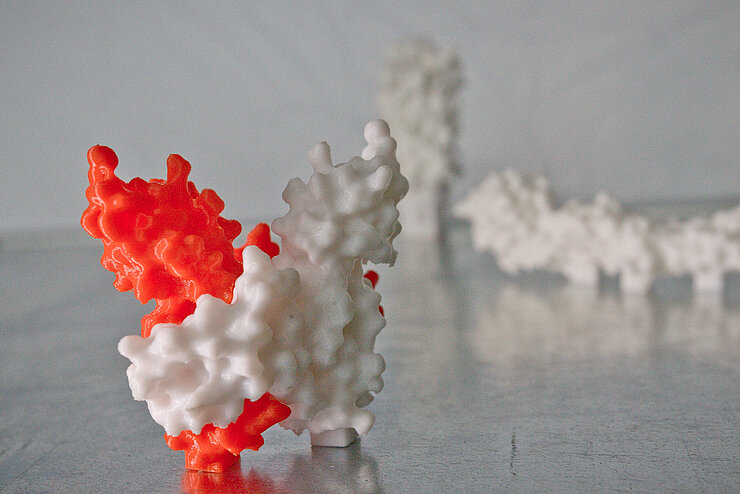

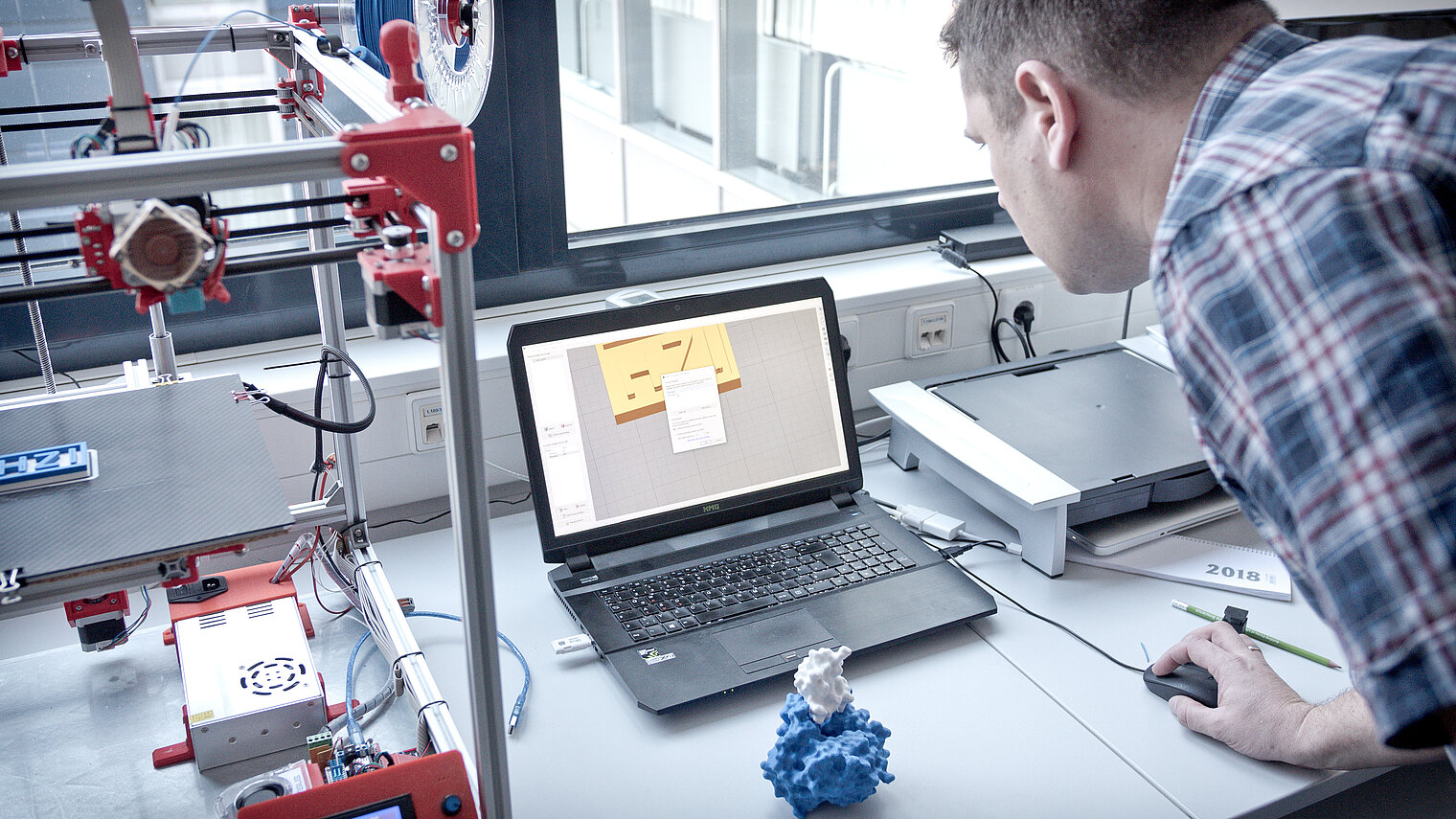

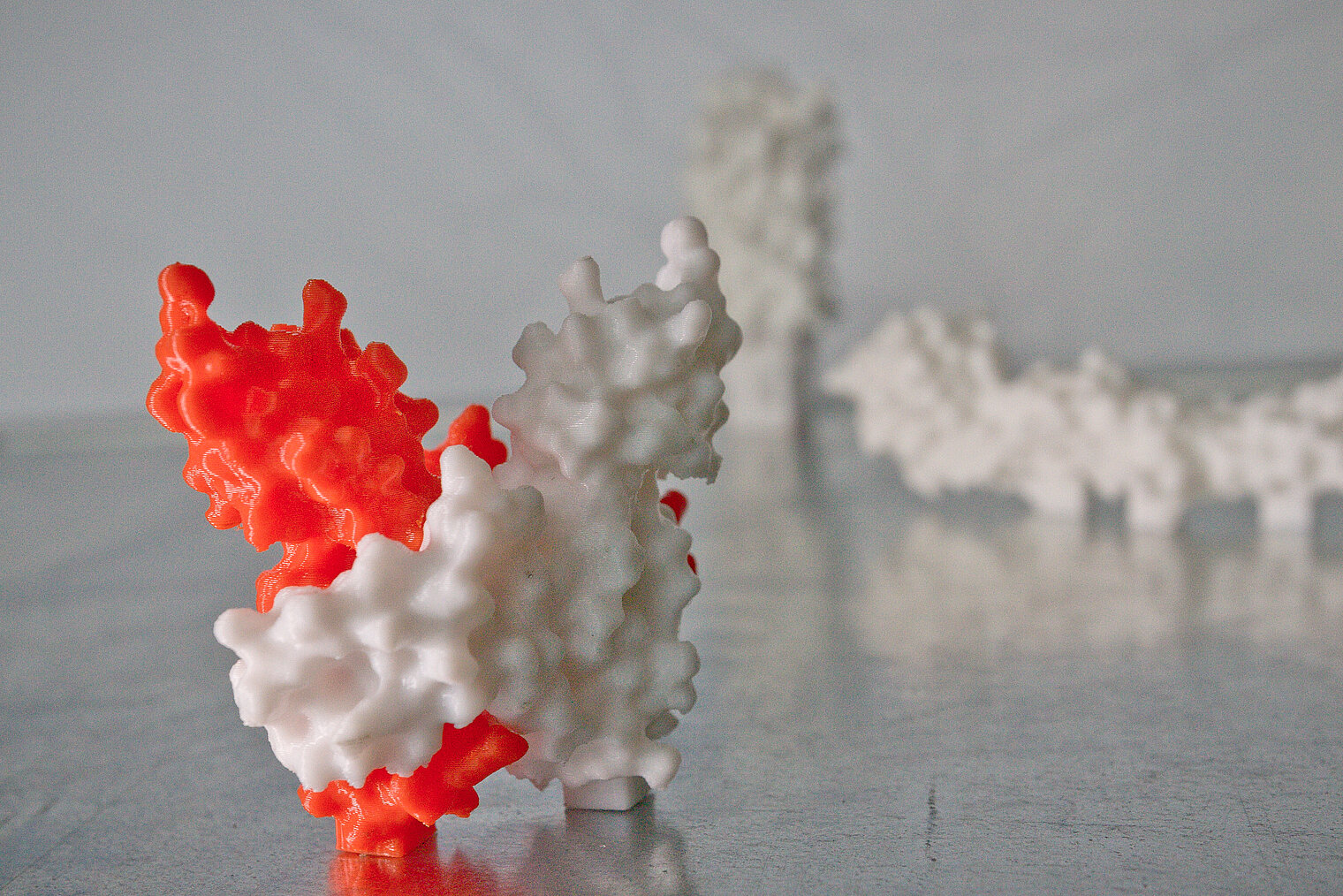

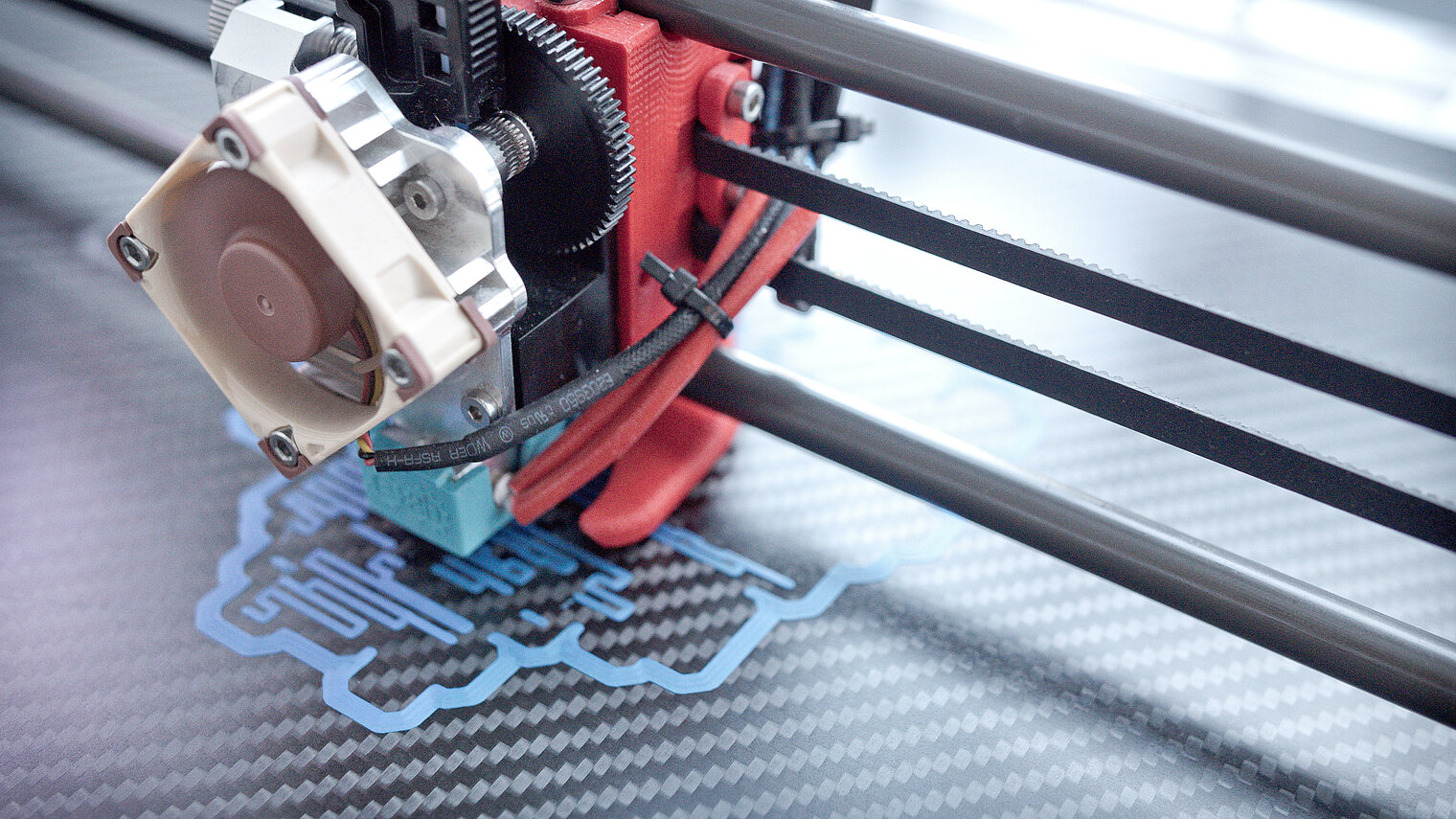

One of his private passions is also very future-oriented: 3D printers and their virtually limitless opportunities. Schmelz designed the second of his two printers himself and implemented it with printed components, then optimised it. He missed special functions, like a bright illumination or a remote control, in his first 3D printer and integrated them step-by-step. The raw material for printing is a thin cable on a reel which is then melted during the printing process in order to build up the desired shape layer-by-layer. He uses a range of different materials, from biologically degradable plastics to copper-containing filament, which looks like shiny metal when polished. He can make functional or decorative things such as an inside-illuminated model of the moon, a reproduction of a sculpture from the Easter Islands – or an InFact sign.