Biosafety Level 3 Laboratory

The BSL3 laboratories

Inside the BSL3 laboratories on the campus of the Helmholtz-Centre for Infection Research our scientists may conduct research with focus on risk group 3 pathogens. BSL3 laboratory installations are isolated plants that are isolated from the outside world, so-called "containments", in which it is ensured that no pathogens can escape unintentionally from the plant. At the HZI, we also train experienced, competent personnel who, in addition to the high scientific requirements, are also able to cope with the high hygienic, technical and organizational requirements of biosafety level 3. The BSL3 platform is operated by the Department of “Safety and Environmental Affairs” at HZI.

You find yourself in the entrance area of the BSL3 facilities. Only a handful of specialized personnel trained for the BSL3 laboratory have access i.e. scientists and their staff. Every person who enters the building is personally registered via the electronic access control. The entrances to technical rooms and a lounge with the log-in station are in this corridor. There is also a wash room and a storage room with the exterior door of the throughput autoclave.

Moreover, the entrance area can be easily transformed into an emergency decontamination site. In case of emergency or evacuation accidentally injured persons can be decontaminated prior to patient transport and submission to hospital. The protective measures as well as the maintenance of the "containment" must also be applied in an emergency.

The BSL3 containment area can only be accessed via the airlock. The door to the laboratory area opens only when the door to the external corridor is closed and air pressure in the lock has been lowered to a negative pressure of -30 Pascal. Alarms will instantly indicate loss of negative pressure or technical problems with the HAVAC system. The airlock is divided into a “clean” and a “potentially polluted” zone. This is where our BSL3 personnel put on their personal protective equipment (PPE) consisting of protective clothing and respiratory protection devices. In the event of a fire a red barrier is latched in front of the door and converts the BSL3 area into an extinguishing water tank that does not release water into the environment.

The staff enters the internal corridor with complete PPE. Here, air pressure is even lower than in the lock to prevent airflow from the internal corridor into the airlock. Emergency phones are available, and anyone who moves in the BSL3 area must carry these on their body so that individuals can be located in case of alarm with these devices. At the same time, they are so-called "dead-man detectors", which automatically emit an emergency signal when they go horizontally with their wearer.

The corridor is also equipped with a C-tube connection - a fire extinguisher - so that in case of fire, no hose from the outside must be placed through open doors. Thus, the "containment" is maintained. In addition, the system is equipped with an automatic extinguishing system, which nebulizes 3600 liters of water at high pressure within ten minutes, stifling every fire in the bud. In addition, the system has a very low fire load as it contains hardly any flammable furnishings.

There is a mobile disinfection station next to the airlock to disinfect the shoes, gloves and respirators before entering the lock when leaving the facility. All laboratory doors are equipped with viewing windows. The green pool and the shower head are eye- and emergency showers.

In the laboratories: Microbiological safety cabinets and high efficiency particulate air (HEPA) filters

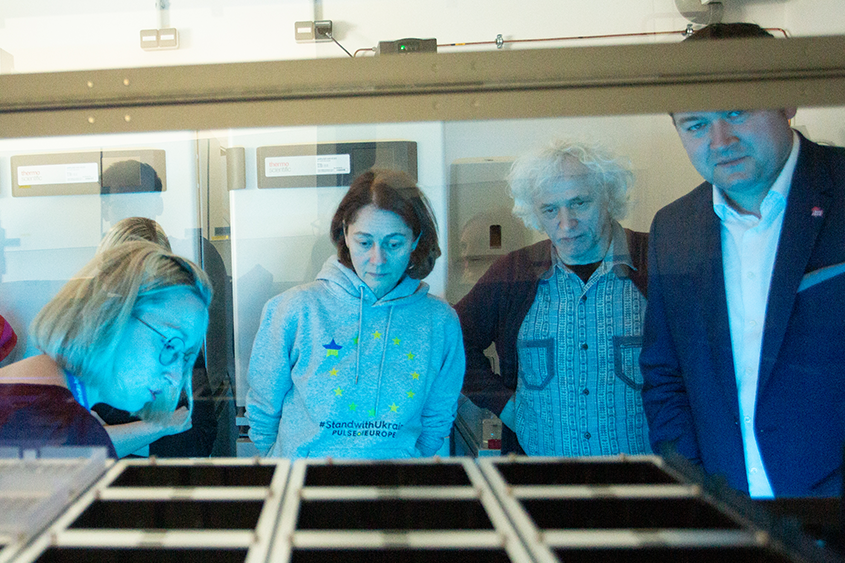

In the laboratories, the air pressure is lowered by a further 30 Pascal compared to the corridor area. Above each door, a digital display shows the current negative pressure. All equipment that our scientists need for their work is located inside the lab to keep pathways with the organisms as short as possible, thus minimizing the risk of accidents. The scientists - here in the laboratories with full PPE - work in the BSL3 area with the microorganisms exclusively under safety cabinets, from which the air is permanently filtered by high efficiency particulate air (HEPA) filters, so-called H14 filters. In addition, the entire air of the BSL3 plant is cleaned by a total of ten independently operating H14 filters.

All steps are documented digitally - no slip leaves the BSL3 lab! And there is no water in the lab, because apart from air, the biggest risk of microbial carryover is water. The only water connections are located in the hallway: firefighting water for the fire brigade and the legally required emergency showers.

The autoclave room plays a central role in the work processes in the BSL3 laboratory. In the autoclave, all materials that have to be removed from the laboratory - such as waste or protective clothing to be cleaned - are heated and sterilized at 2 bar pressure and 121° C with steam. The principle of the BSL3 plant is: Everything leaves the plant through the autoclave, except for the people. The last duty of the working day is loading the autoclave and starting the validated cycle.

The items to be autoclaved are collected in special bins with red lids and autoclaved. Afterwards the respective employee leaves the laboratory via the lock. The other - clean - side of the autoclave can be reached via the entrance area of the laboratory building. The sterile bins can be removed there and their contents can be disposed of safely.

The BSL3 laboratories

Inside the BSL3 laboratories on the campus of the Helmholtz-Centre for Infection Research our scientists may conduct research with focus on risk group 3 pathogens. BSL3 laboratory installations are isolated plants that are isolated from the outside world, so-called "containments", in which it is ensured that no pathogens can escape unintentionally from the plant. At the HZI, we also train experienced, competent personnel who, in addition to the high scientific requirements, are also able to cope with the high hygienic, technical and organizational requirements of biosafety level 3. The BSL3 platform is operated by the Department of “Safety and Environmental Affairs” at HZI.

You find yourself in the entrance area of the BSL3 facilities. Only a handful of specialized personnel trained for the BSL3 laboratory have access i.e. scientists and their staff. Every person who enters the building is personally registered via the electronic access control. The entrances to technical rooms and a lounge with the log-in station are in this corridor. There is also a wash room and a storage room with the exterior door of the throughput autoclave.

Moreover, the entrance area can be easily transformed into an emergency decontamination site. In case of emergency or evacuation accidentally injured persons can be decontaminated prior to patient transport and submission to hospital. The protective measures as well as the maintenance of the "containment" must also be applied in an emergency.

The BSL3 containment area can only be accessed via the airlock. The door to the laboratory area opens only when the door to the external corridor is closed and air pressure in the lock has been lowered to a negative pressure of -30 Pascal. Alarms will instantly indicate loss of negative pressure or technical problems with the HAVAC system. The airlock is divided into a “clean” and a “potentially polluted” zone. This is where our BSL3 personnel put on their personal protective equipment (PPE) consisting of protective clothing and respiratory protection devices. In the event of a fire a red barrier is latched in front of the door and converts the BSL3 area into an extinguishing water tank that does not release water into the environment.

The staff enters the internal corridor with complete PPE. Here, air pressure is even lower than in the lock to prevent airflow from the internal corridor into the airlock. Emergency phones are available, and anyone who moves in the BSL3 area must carry these on their body so that individuals can be located in case of alarm with these devices. At the same time, they are so-called "dead-man detectors", which automatically emit an emergency signal when they go horizontally with their wearer.

The corridor is also equipped with a C-tube connection - a fire extinguisher - so that in case of fire, no hose from the outside must be placed through open doors. Thus, the "containment" is maintained. In addition, the system is equipped with an automatic extinguishing system, which nebulizes 3600 liters of water at high pressure within ten minutes, stifling every fire in the bud. In addition, the system has a very low fire load as it contains hardly any flammable furnishings.

There is a mobile disinfection station next to the airlock to disinfect the shoes, gloves and respirators before entering the lock when leaving the facility. All laboratory doors are equipped with viewing windows. The green pool and the shower head are eye- and emergency showers.

In the laboratories: Microbiological safety cabinets and high efficiency particulate air (HEPA) filters

In the laboratories, the air pressure is lowered by a further 30 Pascal compared to the corridor area. Above each door, a digital display shows the current negative pressure. All equipment that our scientists need for their work is located inside the lab to keep pathways with the organisms as short as possible, thus minimizing the risk of accidents. The scientists - here in the laboratories with full PPE - work in the BSL3 area with the microorganisms exclusively under safety cabinets, from which the air is permanently filtered by high efficiency particulate air (HEPA) filters, so-called H14 filters. In addition, the entire air of the BSL3 plant is cleaned by a total of ten independently operating H14 filters.

All steps are documented digitally - no slip leaves the BSL3 lab! And there is no water in the lab, because apart from air, the biggest risk of microbial carryover is water. The only water connections are located in the hallway: firefighting water for the fire brigade and the legally required emergency showers.

The autoclave room plays a central role in the work processes in the BSL3 laboratory. In the autoclave, all materials that have to be removed from the laboratory - such as waste or protective clothing to be cleaned - are heated and sterilized at 2 bar pressure and 121° C with steam. The principle of the BSL3 plant is: Everything leaves the plant through the autoclave, except for the people. The last duty of the working day is loading the autoclave and starting the validated cycle.

The items to be autoclaved are collected in special bins with red lids and autoclaved. Afterwards the respective employee leaves the laboratory via the lock. The other - clean - side of the autoclave can be reached via the entrance area of the laboratory building. The sterile bins can be removed there and their contents can be disposed of safely.

Organism’s storage

The BSL3 organisms are safely stored at -80°C, encoded and stored under lock and key. Database-driven stock lists and sample logs allow the content and fate of each individual sample to be displayed at any time, even after years.

Team

Selected Publications from the BSL3

Department CBIO (Prof. Dr. Mark Brönstrup):

The myxobacterial metabolite ratjadone A inhibits HIV infection by blocking the Rev/CRM1-mediated nuclear export pathway. Fleta-Soriano E, Martinez JP, Hinkelmann B, Gerth K, Washausen P, Diez J, Frank R, Sasse F, Meyerhans A. Microb Cell Fact. 2014 Jan 29;13:17. doi: 10.1186/1475-2859-13-17.

Identification of myxobacteria-derived HIV inhibitors by a high-throughput two-step infectivity assay.Martinez JP, Hinkelmann B, Fleta-Soriano E, Steinmetz H, Jansen R, Diez J, Frank R, Sasse F, Meyerhans A. Microb Cell Fact. 2013 Sep 24;12:85. doi: 10.1186/1475-2859-12-85.

The Myxobacterial Metabolite Soraphen A Inhibits HIV-1 by Reducing Virus Production and Altering Virion Composition. Fleta-Soriano E, Smutná K, Martínez JP, Lorca Oró C, Sadiq SK, Mirambeau G, Lopez-Iglesias C, Bosch M, Pol A, Brönstrup M, Diez J, Meyerhans A. Antimicrob Agents Chemother. 2017 Jul 25;61(8). pii: e00739-17. doi: 10.1128/AAC.00739-17. Print 2017 Aug

Soraphen A: A broad-spectrum antiviral natural product with potent anti-hepatitis C virus activity. Koutsoudakis G, Romero-Brey I, Berger C, Pérez-Vilaró G, Monteiro Perin P, Vondran FW, Kalesse M, Harmrolfs K, Müller R, Martinez JP, Pietschmann T, Bartenschlager R, Brönstrup M, Meyerhans A, Díez J. J Hepatol. 2015 Oct;63(4):813-21. doi: 10.1016/j.jhep.2015.06.002. Epub 2015 Jun 10

Patents:

Brönstrup M., Prochnow H., Birudukota N. V. S., Schulz T., Messerle M., Pietschmann T., Haid S., Blockus S., Laqmani-Goffinet C., Franz S., Banda D., (2017) Labyrinthopeptins As Anti-Viral Agents Pa-tent No. WO/2017/085257, International Patent No. PCT/EP2016/078143

Department INFG, Prof.Dr. Klaus Schughart:

Kanrai P, Mostafa A, Madhugiri R, Lechner M, Wilk E, Schughart K, Ylösmäki L, Saksela K, Ziebuhr J, Pleschka S. Identification of specific residues in avian influenza A virus NS1 that enhance viral replication and pathogenicity in mammalian systems. J Gen Virol. 2016 Sep;97(9):2135-48.

Long-term neuroinflammation induced by influenza A virus infection and the impact on hippocampal neuron morphology and function. Shirin Hosseini, Esther Wilk, Kristin Michaelsen-Preusse, Ingo Gerhauser, Wolfgang Baumgärtner, Robert Geffers, Klaus Schughart, Martin Korte. Journal of Neuroscience; in press.

Hatesuer B, Bertram S, Mehnert N, Bahgat MM, Nelson PS, Pöhlmann S, Schughart K. Tmprss2 is essential for influenza H1N1 virus pathogenesis in mice. PLoS Pathog. 2013;9(12):e1003774.

Kühn N, Bergmann S, Kösterke N, Lambertz RL, Keppner A, van den Brand JM, Pöhlmann S, Weiß S, Hummler E, Hatesuer B, Schughart K. The Proteolytic Activation of (H3N2) Influenza A Virus Hemagglutinin Is Facilitated by Different Type II Transmembrane Serine Proteases. J Virol. 2016 Apr 14;90(9):4298-307.

Research Group IMMI, Prof. Dr. Andrea Kröger:

Asghar N, Lee YP, Nilsson E, Lindqvist R, Melik W, Kröger A, Overby AK, Johansson M (2016) The role of the poly(A) tract in the replication and virulence of tick-borne encephalitis virus. Scientific reports 6: 39265

Kurhade C, Zegenhagen L, Weber E, Nair S, Michaelsen-Preusse K, Spanier J, Gekara NO, Kröger A*, Overby AK* (2016) Type I Interferon response in olfactory bulb, the site of tick-borne flavivirus accumulation, is primarily regulated by IPS-1. Journal of neuroinflammation 13: 22

Lindqvist R, Mundt F, Gilthorpe JD, Wolfel S, Gekara NO, Kröger A, Overby AK (2016) Fast type I interferon response protects astrocytes from flavivirus infection and virus-induced cytopathic effects. Journal of neuroinflammation 13: 277

Weber E, Finsterbusch K, Lindquist R, Nair S, Lienenklaus S, Gekara NO, Janik D, Weiss S, Kalinke U, Overby AK*, Kröger A* (2014) Type I interferon protects mice from fatal neurotropic infection with Langat virus by systemic and local antiviral responses. Journal of virology 88: 12202-12212